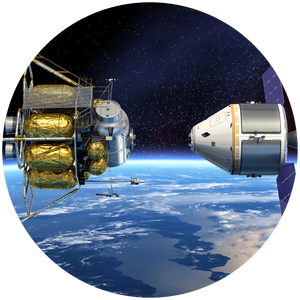

Enabling Progress in Space and defence

Advancements in space and defense sectors rely on cutting-edge research in metals, alloys and advanced materials.

From aerospace components to high-performance structures for critical environments, success depends on precision engineering and rigorous quality standards. Our technologies support these industries with particle characterization, elemental analysis, thermal processing, mechanical testing and sample preparation - driving innovation and reliability in materials science for space and security applications.

Our expert and professional team will support you finding the perfect solution!

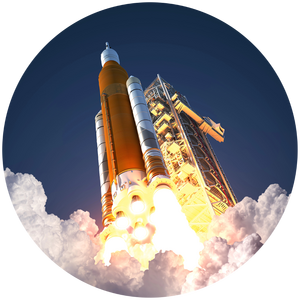

Modern rocket engines are now routinely manufactured using advanced 3D printing techniques, enabling optimal structural stability, reduced weight, and integrated cooling channels that were previously impossible to produce with conventional methods. This breakthrough in additive manufacturing has transformed the production of complex components such as missile parts and aircraft engine elements, where performance and reliability are paramount.

In these applications, metal powders—especially titanium and steel—play a critical role. For processes like 3D printing or thermal spray coating, the powders must exhibit tightly controlled particle size distributions to ensure consistent and reliable processing. Generally, spherical particles within a narrow size range are preferred, as they flow more easily and can be deposited more uniformly. However, if the size range is too narrow, packing density decreases, potentially leading to voids and inhomogeneities in the final component.

Microtrac offers a comprehensive portfolio of technologies for analyzing particle size and shape, including both dry and wet dispersion methods. Their systems are designed to meet the stringent demands of aerospace and defense manufacturing. In this application note, Microtrac demonstrates how Dynamic Image Analysis (DIA) — as implemented in the CAMSIZER X2 - provides deep insight into powder quality. Unlike traditional sieving, DIA can detect even 0.005% of oversized particles, ensuring that only powders meeting the highest standards are used in production.

Surface area analysis of metal powders is crucial in defense and security applications, where material performance under extreme conditions is paramount. The specific surface area influences properties such as reactivity, sintering behavior, and mechanical strength, which are vital for components like armor, propulsion systems, and additive manufacturing parts. Microtrac's BELSORP series, including the BELSORP MAX X, MAX G, and MINI X, offers advanced capabilities for precise surface area and pore size distribution measurements. These instruments utilize gas adsorption techniques, adhering to standards like ASTM B922 and ISO 9277, ensuring reliable and reproducible results.

Have a look to the list of Standard compliance to Microtrac product:

The BELSORP MAX X stands out with its ability to analyze up to four samples simultaneously, covering a wide range of pressures and temperatures. It supports various adsorbates, enabling comprehensive characterization of materials. The BELSORP MAX G, with its ultra-low pressure measurement capability, is ideal for evaluating micro-, meso-, and macroporous materials.

Propulsive & Propellants

| Distribution (percentile-weight %) | Microns |

|---|---|

| 10 % | 1.4+/-0.1 |

| 50% | 4.2+/-0.3 |

| 90% | 10.5+/-0.5 |

| Mean | 5.2+/-0.5 |

Lorem ipsum dolor sit amet, consectetuer adipiscing elit.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulput

.

Quisque rutrum. Aenean imperdiet. Etiam ultricies nisi vel augue. Curabitur ullamcorper ultricies nisi. Nam eget dui. Etiam rhoncus. Maecenas tempus, tellus eget condimentum rhoncus, sem quam semper libero, sit amet adipiscing sem neque sed ipsum. Nam quam nunc, blandit vel, luctus pulvinar, hendrerit id, lorem. Maecenas nec odio et ante tincidunt tempus. Donec vitae sapien ut libero venenatis faucibus. Nullam quis ante. Etiam sit amet orci eget eros faucibus tincidunt. Duis leo. Sed fringilla mauris sit amet nibh. Donec sodales sagittis magna. Sed consequat, leo eget bibendum sodales, augue velit cursus nunc,

Quisque rutrum. Aenean imperdiet. Etiam ultricies nisi vel augue. Curabitur ullamcorper ultricies nisi. Nam eget dui. Etiam rhoncus. Maecenas tempus, tellus eget condimentum rhoncus, sem quam semper libero, sit amet adipiscing sem neque sed ipsum. Nam quam nunc, blandit vel, luctus pulvinar, hendrerit id, lorem. Maecenas nec odio et ante tincidunt tempus. Donec vitae sapien ut libero venenatis faucibus. Nullam quis ante. Etiam sit amet orci eget eros faucibus tincidunt. Duis leo. Sed fringilla mauris sit amet nibh. Donec sodales sagittis magna. Sed consequat, leo eget bibendum sodales, augue velit cursus nunc,

| a | 123 | text |

| b | 124 | text |

| c | 123 | text |